Sludge treatment disposal and utilization 污泥处理处置与资源化

Utilization of sludge resource

At present, sludge treatment and disposal methods mainly include land landfill, land use, incineration and resource recovery. The sludge treatment methods developed by the laboratory on the basis of existing research foundation include:

1. Utilization of Sludge Construction Material

The utilization of sludge building material is an important way of waste resource utilization at present. Sludge incineration will produce a large amount of fly ash, and this part of sludge fly ash can be used to produce industrial building materials (such as cement, brick, ceramsite, etc.), which will greatly reduce the use of natural resources, thereby effectively avoiding environmental damage. Sludge contains a lot of ash, which is a kind of clay resource. At the same time, the sludge treated by coagulation process contains a lot of aluminum, iron and other components. It can be used as additives for building materials, so that sludge can be used as good industrial raw materials to make building materials. On the basis of existing research, geopolymer cementitious materials with good physical, chemical and mechanical properties were prepared by sludge fly ash, red mud and other related substances in the laboratory.

2. Sludge dewatering

Sludge must be stabilized, reduced and sanitized before landfill. The Ministry of Ecological Environment of China has made strict requirements on the moisture content of sludge which was used for landfill (water content of sludge is less than 60%). Because of the hydrophilic structure of sludge flocs, water in sludge will be combined in different forms. According to the different binding forms, the water in sludge can be divided into free water, interstitial water, surface binding water and intracellular water. At present, mechanical dewatering can not effectively remove the bound water in sludge, so before mechanical dewatering of sludge, it is generally necessary to improve the dewatering performance of sludge through physical, chemical or physical chemical action. The structure of sludge can be changed and its viscosity can be reduced by conditioning. After the sludge is conditioned, not only the dewatering pressure decreases, but also the water content of the sludge can be greatly reduced after dewatering. Based on the existing research foundation, the laboratory enhanced the release of bound water by chemical agents and electrochemical action, thereby enhancing the deep dewatering performance of sludge.

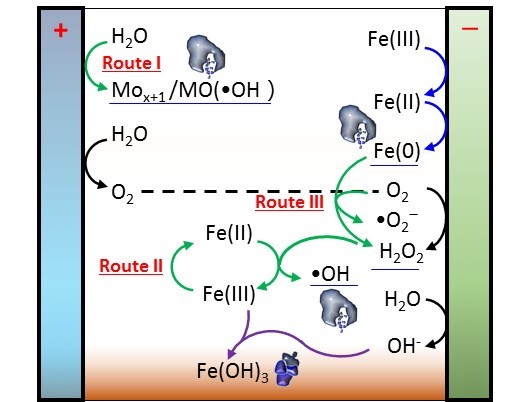

Fig. 1. Mechanism of sludge dewatering performance with the hybrid electrooxidation conditioning method: process diagram of the related representative oxidation routes (Routes I, II and III) and the coagulation process in the hybrid conditioning strategy

3. Sludge anaerobic fermentation

Anaerobic fermentation process has the advantages of low energy consumption, high organic load and bioenergy recovery. Sludge anaerobic fermentation is a process of transforming organic matter such as protein and carbohydrate, in which organic matter acts as an electron acceptor and also provides electrons for microorganisms. Sludge anaerobic fermentation process mainly includes hydrolysis, acidification and hydrogen production to produce acetic acid. Organic matter is decomposed by microorganisms and eventually converted into harmless biogas as fuel. Based on the existing research foundation, our laboratory strengthens the release of organic matter in sludge by advanced oxidation and electrochemical action, and strengthens the electron transfer of microorganisms, so as to achieve effective biogas generation.

4. Removal of Heavy Metals from Sludge

Sludge contains a lot of refractory organic matter, heavy metals, pathogenic microorganisms and parasite eggs. However, sludge is rich in nutrients and high calorific value, which is a reusable "resource". Land use is considered to be one of the most effective ways to treat sludge resources, but heavy metals in sludge, as a persistent potential toxic pollutant, are the main reasons for restricting large-scale land use of sludge. At present, sludge heavy metal removal technologies mainly include solidification/stabilization, chemical extraction, bioleaching process, phytoremediation and electrokinetic process. The laboratory has achieved the purpose of using organic matter in sludge by removing heavy metals mainly through improved solidification/stabilization, chemical and electrochemical remediation methods.

5. Recovery of phosphorus from sludge

At present, the unidirectional flow of phosphorus in the biosphere makes it a valuable non-renewable resource. In the world, phosphorus ore reserves are very limited, available phosphorus resources are scarce, and phosphorus resources in sludge are abundant and renewable, so the recovery of phosphorus from sludge has attracted the attention of many scholars. If phosphorus is recovered from sewage sludge and the technology of phosphorus recovery is constantly improved, it can not only prevent water pollution, but also realize the recycling of phosphorus in natural environment. At present, the methods of recovering phosphorus include crystalline struvite precipitation, calcium phosphate precipitation, iron and aluminium salt precipitation, adsorption and so on. On the basis of existing research, the laboratory mainly enhanced phosphorus release from sludge by chemical and electrochemical methods (MEC), and then realized phosphorus recovery from sludge by crystallization method.

污泥资源化

当前,污泥处理处置手段主要包括土地填埋,土地利用,焚烧及回收资源等方法。目前实验室根据已有的研究基础发展的污泥处理手段包括:

1,污泥建材化利用

污泥建材化利用是当前比较重要的一种废物资源化利用的方式。由于污泥焚烧之后会产生大量飞灰,如果能够利用这部分污泥飞灰制作工业上的建材(如水泥、砖材、陶粒等)将会大幅减少自然资源的使用,从而有效避免破坏环境。污泥中含有大量的灰分是一种黏土质资源,同时被混凝法处理后的污泥中含有大量的铝、铁等成分,可作为建筑材料添加剂,使污泥能够作为良好的工业原料制作建筑材料。实验室在已有的研究基础上通过污泥飞灰、赤泥及其它相关物质制备具有良好的物理化学和机械性能的地聚物胶凝材料。

2,污泥脱水

污泥填埋前必须对污泥进行稳定化、减量化和卫生化处理,国家生态环境部对用于填埋的污泥的含水率做了严格要求(污泥含水率低于60%)。由于污泥絮体的亲水性结构,导致污泥中的水分会以不同形式跟污泥进行结合。根据结合形式的不同,可以将污泥中的水分为自由水、间隙水、表面结合水和细胞内部水。目前机械脱水不能有效将污泥中的结合水去除,所以在污泥机械脱水之前一般需要通过物理、化学或物理化学作用,改善污泥的脱水性能。通过调理可改变污泥的组织结构,减少其黏性。污泥经调理后,不仅脱水压力减少,而且脱水后污泥的含水率可大大降低。实验室根据已有的研究基础,通过化学药剂和电化学作用强化污泥中结合水的释放,从而增强污泥的深度脱水效果。

3,污泥厌氧发酵

厌氧发酵处理过程具有能耗少,能承受高有机负荷且可回收生物能的优点。污泥厌氧发酵是一个将蛋白质和碳水化合物等有机物转化的过程,有机物在这个过程当中既作为电子受体也为微生物提供电子。污泥厌氧发酵过程主要包括水解、酸化和产氢产乙酸三个阶段,有机物被微生物分解最终转化为无害的可作为燃料的沼气。我们实验室根据已有的研究基础,通过高级氧化作用和电化学作用强化污泥中有机物释放,并强化微生物的电子传递作用,从而实现有效的沼气生成。

4,污泥中重金属去除

污泥中含有大量难降解有机物,重金属以及病原微生物和寄生虫卵等。但污泥中又具有丰富的营养物质和较高的热值,是可再利用的“资源”。其中土地利用被认为是污泥资源化的最有效的处理方式之一,但污泥中所含的重金属作为一种持久性潜在有毒污染物,是限制污泥大规模土地利用的主要原因。目前污泥重金属去除技术主要包括固化/稳定化,化学法,微生物沥滤法、植物修复法和电动修复法等技术。实验室通过已有基础主要通过改进型的固化/稳定化、化学法和电动修复法去除污泥中重金属,达到污泥中有机物利用的目的。

5,污泥中磷元素的回收

目前,磷在生物圈的单向流动使之成为一种不可再生的宝贵资源。世界上磷矿石的储量十分有限,可利用的磷资源短缺,而污泥中的磷资源丰富且可再生,所以回收污泥中磷得到各界学者的关注。如果从污水污泥中回收磷并不断完善回收磷的技术,不仅能防止水污染,还能实现自然环境中磷的循环利用。目前,回收磷的方法包括结晶鸟粪石、磷酸钙沉淀法、铁盐和铝盐沉淀法、吸附法等。实验室在已有的研究基础上,主要通过化学法和电化学法(MEC)增强污泥中磷的释放,再通过结晶法实现污泥中磷的回收。